Expert Council

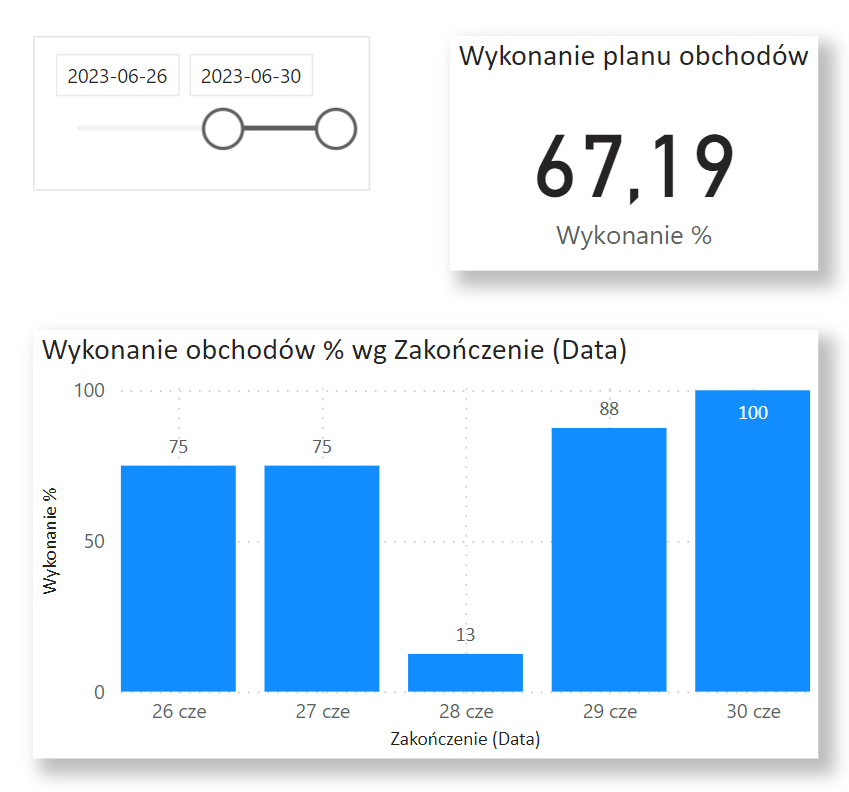

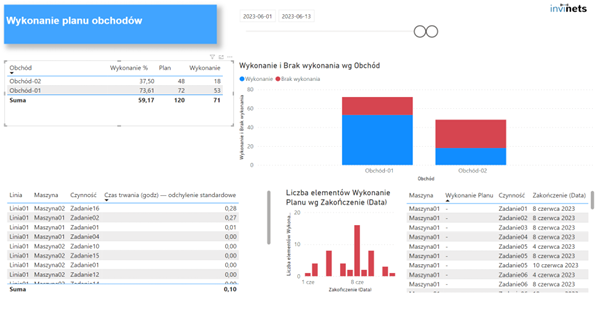

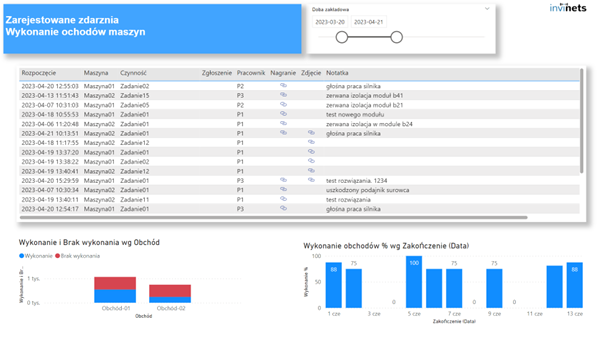

To make the most of the rounds, they should include recording any irregularities - preferably with photos and voice notes. It is also a good idea to monitor the implementation of all points in the process on an ongoing basis, and collect the information and reports in one place. This will allow you to quickly and easily analyze trends and thus make more effective decisions and strategies.

InspectoFLow will help you with all this, where you can track the execution of planned rounds, report irregularities by taking photos and notes. All data is recorded to our MAPS cloud and ready for download and analysis in Excel or Power BI.